Thread Mill Technical

ABOUT OUR THREAD MILLS

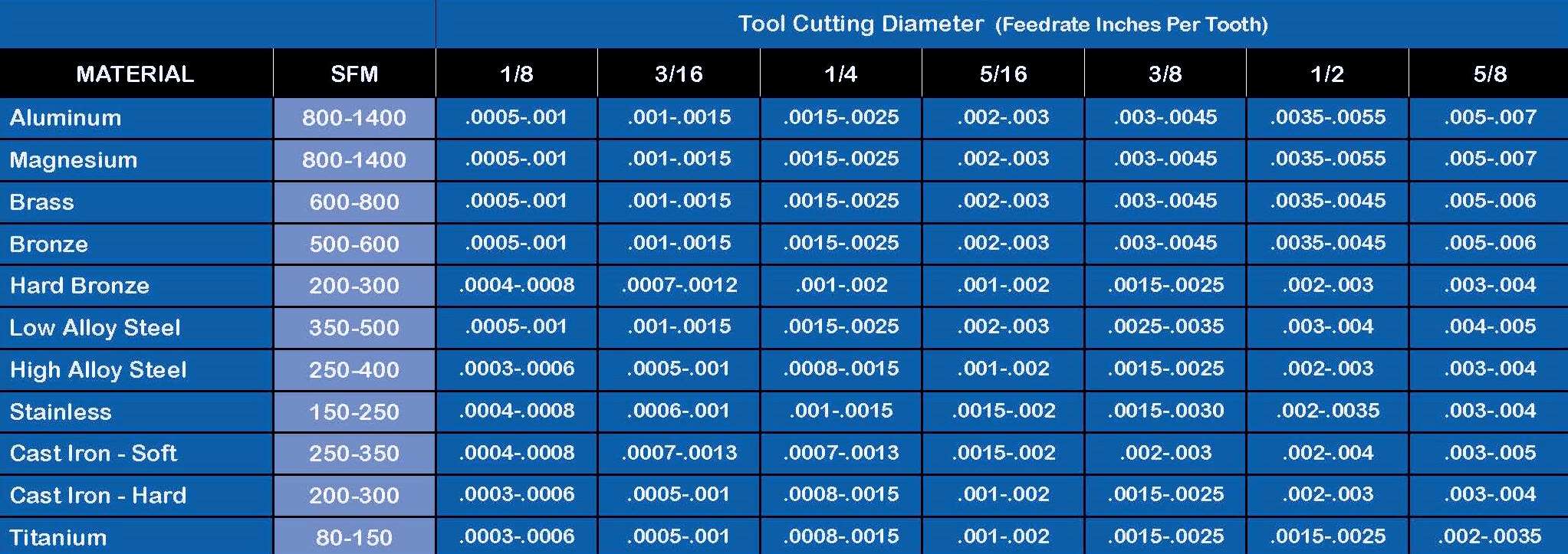

RTJ Tool Company manufacturers a full line of Thread Mills for any threading application. Our premium carbide AlTiN coated thread mills have helical flute geometry. This dramatically reduces cutting pressure which results in higher feed rates, faster cycle times, better surface finish and accuracy, and lower cost per hole. All thread mills are AlTiN coated.

STANDARD THREAD MILL TECHNICAL

1. ALWAYS REDUCE FEED RATE BY 50% WHEN RAMPING IN TO THE CUT

2. MULTIPLE PASSES RECOMMENDED FOR THREAD MILLING STEEL

3. DO NOT RE-CUT CHIPS - COOLANT BLAST RECOMMENDED

4. A THREAD MILL CAN PRODUCE VARIOUS SIZES WITH THE SAME PITCH

ABOUT METRIC THREAD MILLS

A 2.00 pitch tool can be used to cut any 2.00 pitch thread as long as the thread mill has a long enough flute length (LOC) to complete the thread. A complete line of premium quality solid carbide metric thread mills in stock.

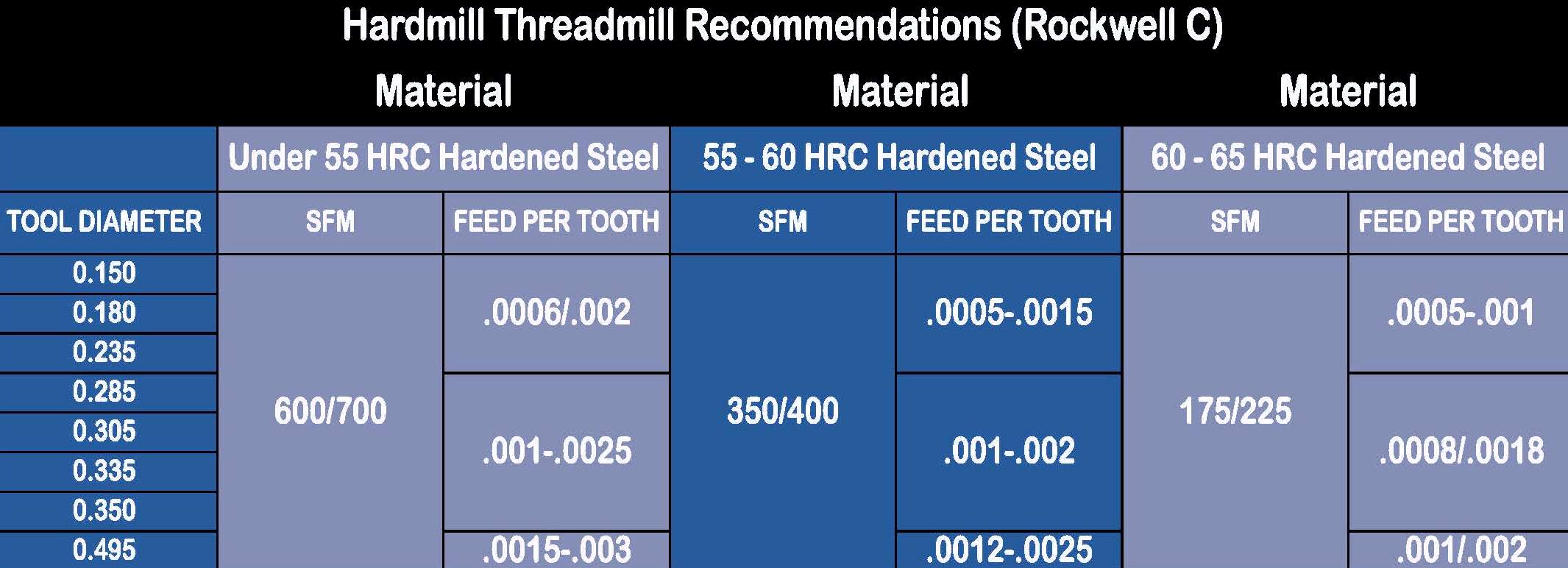

ABOUT HARD MILL THREAD MILLS

RTJ Tool Company's breakthrough design allows thread milling in materials hardened up to 62 Rc. Our variable flutes, high hardness and heat resistant nACo coating allow you to mill threads in hardened steels that taps cannot cut.

- Hard mill Thread mills should be run with air blast NOT coolant.

- Always reduce feed rate by 50% when ramping in to the cut.

- Evacuate chips properly while milling. Recutting chips will damage cutter.

- Hard mill Thread milling requires several small radial cuts or “step overs“.

- We recommend 7 passes for fine threads and 9 passes for coarse threads.

- Thread interpolation should spiral from bottom of thread in upward direction.

HOW TO CALCULATE HARD MILL THREAD MILL RADIAL PASSES

Example thread: 1/4"-28

Major thread diameter you are cutting: 0.250"

Minor hole diameter: 0.213"

1. Determine stock to be removed: 0.250" - 0.213" = 0.037"

2. Determine stock per side to be removed: 0.037"/2 = 0.0185"

3. Multiply 0.0185" by the recommended percentages per pass (below) for approximate radial depth of cut.

(RADIAL DEPTH OF CUT IN X OR Y)

1st Pass = .0185 X 23% = .0045 (add any leftover to first pass)

2nd Pass = .0185 X 23% = .004

3rd Pass = .0185 X 16% = .003

4th Pass = .0185 X 16% = .003

5th Pass = .0185 X 11% = .002

6th Pass = .0185 X 11% = .002

7th Pass = FREE PASS